When the SSAB plant in Raahe entered into agreement with Telinekataja in early 2021, safety was the priority theme for negotiations. “Going home healthy. This is the most important goal for everyone working at SSAB. Together we take responsibility for interruptions, servicing, and occupational safety”, summarises SSAB’s Raahe plant’s Maintenance Manager Aki Karppinen.

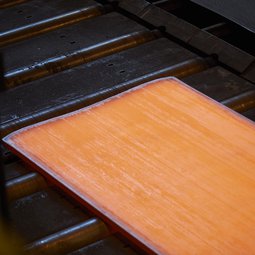

Stainless steel hot-rolled flat products and coil products are the main products of the Raahe plant. SSAB Raahe is a pioneer heading for the manufacturing of fossil-free steel, with the goal of eliminating the majority of its carbon dioxide emissions by around 2030.

The SSAB Raahe plant manufactures so-called standard, premium, and special steels. The main products are hot-rolled sheets and coil products. The plant area comprises a number of plants within a plant, and covers an area of approximately 500 hectares. Two furnaces produce raw iron that is refined into steel at the steel foundry. Steel billets are formed using the molten steel, which is rolled into products at the hot rolling mill. The plant area also has a coking plant, power plant, its own harbour, and one of Finland’s largest laboratory complexes.

Established almost 60 years ago, the Rautaruukki Raahe plant grew to become the largest integrated steel factory in the Nordic nations. Now SSAB Raahe is looking into the future and acts as a pioneer in producing fossil-free steel. The technical planning for the change at the Raahe plant commenced in 2020. With an innovative Nordic production system, SSAB aims to eliminate the majority of its carbon dioxide emissions by around 2030.

SSAB has around 2,500 of its own employees working at the plant site, and hundreds of subcontractor and partner employees. The maintenance team comprises around 800 employees. Around 180 employees work in centralised maintenance.

Aki Karppinen feels that over the course of his 11-year career at SSAB, the role of safety has been further enhanced “What needs to be visible on a day-to-day basis is that everyone working at SSAB – both our own employees and our partners’ employees – arrives home healthy”.

SSAB and Telinekataja entered into a national agreement in early 2021. When SSAB requested tenders from a few scaffolding suppliers, the requirements and preferences defined by SSAB’s maintenance and procurement organisation were examined together.

“Safety was also the priority topic in contract negotiations. Following instructions, risk assessments, induction procedures, training sessions... all these have to be in order. In addition to fossil-free technology, we expect our contractual partners to be flexible, efficient, and able to evolve, and develop its activities.

We have now completed the first year of this three-year contract”, says Aki Karppinen, summing up his satisfaction of the experience.

“Telinekataja has actively participated in improving occupational safety. Management and installers have made safety observation entries into or electronic system. This is what we expected. The site is a worksite that we share, so each pair of eyes has its own role to play. Each one of us is unique, and the professionals from different sectors view working environments in different ways”.

According to Karppinen, cooperation works well on all levels. From individual scaffolding requirements, between different functions and work management teams, and project management – both in the field and in quarterly meetings.

“A good team spirit where communication is key is something I value. Open relations ensure that problems can be solved and activities developed. Together we hold responsibility for production interruptions, servicing, and occupational safety aspects. Together we take into consideration the scaffolding requirements and resources”.

As a whole, maintenance holds a key position, enabling the production of SSAB’s Raahe plant to run fluently and according to goals. Around twenty contract partner scaffolding installers operate on the site every day, with the number of employees being 60–70 scaffolding professionals on site during larger interruptions. Telinekataja’s local warehouse, its Oulu office and Northern Finland professionals are close to Raahe.

The everyday maintenance work ar SSAB’s Raahe plant is meticulously planned in advance. Aki Karppinen’s Excel worksheet illustrates how the 33-point annual maintenance programme is steadily progressing.

SSAB’s Raahe plant has two furnaces producing raw iron that is refined into steel at the steel foundry. Steel billets are formed using the molten steel, which is rolled into products at the hot rolling mill

Every weekday, there is weekly maintenance being performed somewhere on the SSAB site. The smaller servicing operations are performed using a team of a few people, whereas larger teams comprise hundreds of professionals.

“The majority of maintenance is forecasted and according to plan. We are conducting weekly maintenance somewhere in the plant every weekday. The smaller servicing operations are performed using a team of a few people, whereas larger teams comprise hundreds of professionals. For instance, the coil mill servicing had both our own staff and external partners on site, to a total of 55 employees.

The goal for regular annual maintenance and good forecasting is to ensure there will be no surprises. In fault events and other unplanned maintenance requirements, the first thing that is checked at the SSAB Raahe plant is if our own organisation erects the required scaffolds, or will Telinekataja be commissioned for the task. The SSAB and Telinekataja counterparts make a scaffolding plan on site, which is an absolute prerequisite for erecting scaffolding. The revision protocol has to be signed off prior to commencing any work on the scaffolds. The process progresses immediately, within a few hours.

Alongside reactive ability and flexibility with demanding fault events and planned weekly and annual maintenance, Aki Karppinen considers continuous development work between the contractual partners and production equally important – with the goal of safety, productivity, and quality. Information and experiences are also exchanged between SSAB’s various plants.

“Following the successful completion of the first contractual year with Telinekataja, our shared goal is joint development projects, such as the introduction of an electronic scaffold management system, and a variety of pilot sites”, Ari Karppinen pleasingly adds.